| Source Factory Directly

Custom Investment Casting Foundry & CNC Machining Supplier

Custom Investment Casting Manufacturer and CNC Machining Company

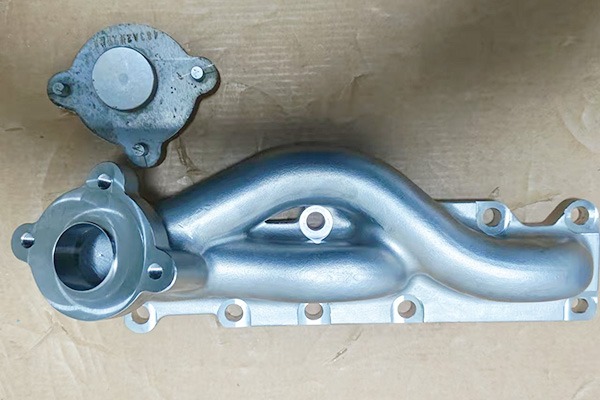

JC Casting is a professional investment casting foundry with extensive experience. Especially in large-scale supply chain operations. Our vertically integrated manufacturing process covers the entire casting, from the initial master melt to the delivery of ready-to-install castings, including all mechanical processing,CNC machining, surface finishing, and assembly.

23+

yEARS

12

ENGINEERS

200+

STAFF

90%

EXPORTED

High-Quality Services From Our State-of-the-Art Precision Casting Foundry

JC Casting is one of the best casting foundries and manufacturers in China. Especially for investment casting, precision casting, lost wax casting, steel investment casting. For OEM custom parts — from prototype to mass production.

We produce high-precision investment castings for industries such as automotive, aerospace, energy, mechanical engineering, and medical technology.

- Investment Casting | Sand Casting | Die Casting | CNC Machining

- Steel,Alunimum,Bronze,Brass and Ti Alloy Are Our Core Material

- ISO Certified · Strict Quality Control

- Fast Quotation · Drawing-based Manufacturing

Core Capabilities

We can provide 4 main investment casting processes (Inlcuding silca sol investment casting and water glass casting),die casting,sand casting and CNC machining service. Accept multiple types and small orders. Support Both Low Volume And Large Volume Production. Especially in long-term supplying and managment service!

Typical Material Casting Products

Stainless Steel Casting

Excellent corrosion resistance. Ideal material for casting components in industries. Such as food machine, marine, and chemical industry. Usually requiring little to no additional machining. Common stainless steel grades: 304(L), 316(L), 17-4 PH, and 2205 duplex.

Carbon Steel Casting

Good strength, ductility, and cost – effectiveness. It is used in construction, automotive, and heavy machinery. Common carbon steel grades: WCB,LCB,Q235 (equivalent to ASTM A36), Q345, ASTM A335, DIN C35 (1.0501), and C45 (1.0503).

Alloy Steel Casting

Outstanding strength, durability, and versatility. It contains specific alloying elements. Widely used in high-stress applications: aerospace, automotive, and heavy machinery industries. JC Casting can meet strict performance standards, delivering reliable solutions for demanding projects. Alloy steel grades: 20CrMo,42CrMo, AISI 4140 and 4340.

Aluminum

Casting

Light weight, excellent corrosion resistance, and high thermal conductivity. It is widely used in aerospace, automotive, and electronics. produce by die casting, sand casting process.These parts are accurate in dimensions, surface finishes, and outstanding mechanical properties. Common aluminum grades:A356, A380, and 6061 or special AlSi10Mg Casting.

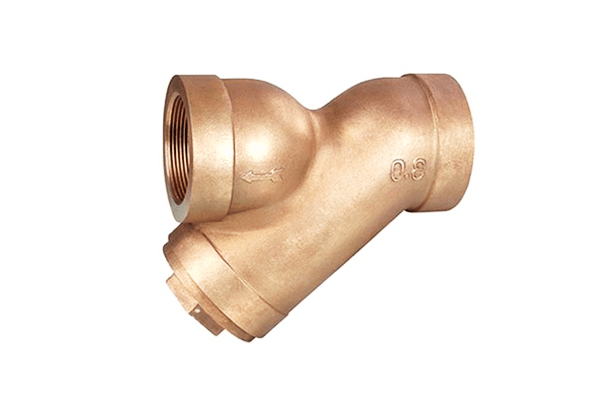

Bronze Casting

Bronze casting is a long history high – quality product. Bronze is an alloy mainly composed of copper and tin, sometimes with other elements. We can produce bronze casting parts by sand casting and investment casting process. Common bronze grades we use: C90300 (SAE 64), C93200 (SAE 660), and C95400.

Brass Casting

outstanding ductility, corrosion-resistant properties, and shining surface. plumbing, hardware, and decorative arts. JC Casting produces premium-quality brass casting products. Our brass castings distinguish themselves with accurate dimensions, smooth surface finish,good mechanical strength. The popular brass grades: C26000, C36000, and C46400.

Ti Alloy Casting

Exceptional strength-to-weight ratio, high-temperature resistance, superior corrosion resistance. Used in aerospace, automotive and marine engineering. We use the Vacuum precision casting process and CNC machining. The popular Ti Alloy grades are Ti-6Al-4V, Ti-5Al-2.5Sn, and Ti-6Al-2Sn-4Zr-2Mo.

Iron Casting

excellent strength, durability,low material cost. It is an ideal material in industries such as construction, machinery manufacturing, and automotive. At JC Casting Foundry,we have sand casting and lost foam casting techniques to produce cast iron casting parts. We commonly use gray iron (ASTM A48),ductile iron (ASTM A536).

Industry Applications

JC Casting provide tailored casting solutions for your industry challenges. We deliver precision casting solutions engineered to solve the real performance, durability, and compliance issues across demanding applications.

Areospace

Solution: Lightweight, high-strength castings with full traceability.

Automotive

Solution: Precision castings for high-volume, cost-efficient production

Agricultural

Solution: Heavy-duty cast parts built for harsh environments.

Food Machinery

Solution: Strict hygiene, corrosion resistance, and food-grade compliance requirements.

Marine

Solution: Corrosion-resistant castings for marine conditions.

Medical

Solution: High-precision castings with strict quality control.

Mining

Solution: Wear-resistant castings for extreme conditions.

Fluid equipment

Solution: Pressure-tight, dimensionally stable castings..

Train and Railway

Solution: Add a brief description to your card.

Factory Show

JC Casting is a comprehensive foundry. From mold design, casting to inspection and testing. We can operate independently to meet your different needs! You can get one-stop service here.

Project Team

Mould Workshop

Investment Casting Workshop

Sand Casting Workshop

Die Casting Workshop

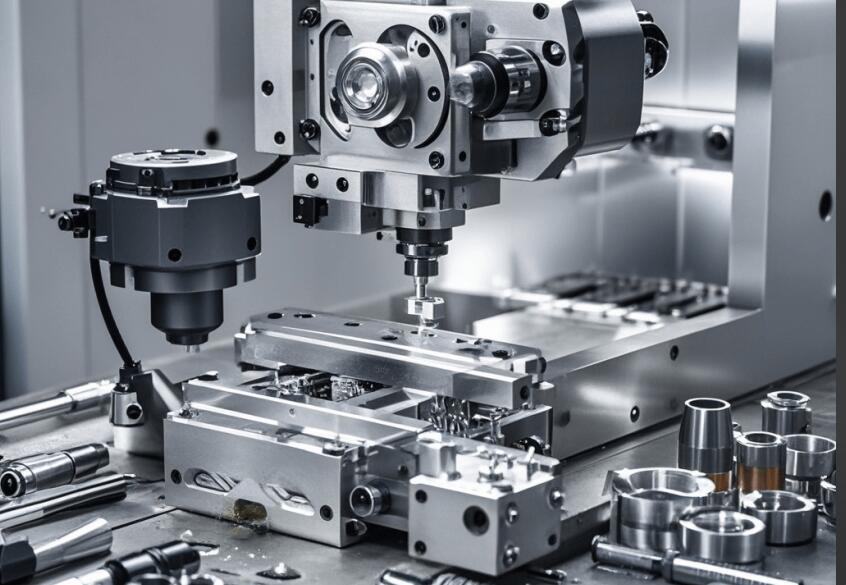

CNC Machining Workshop

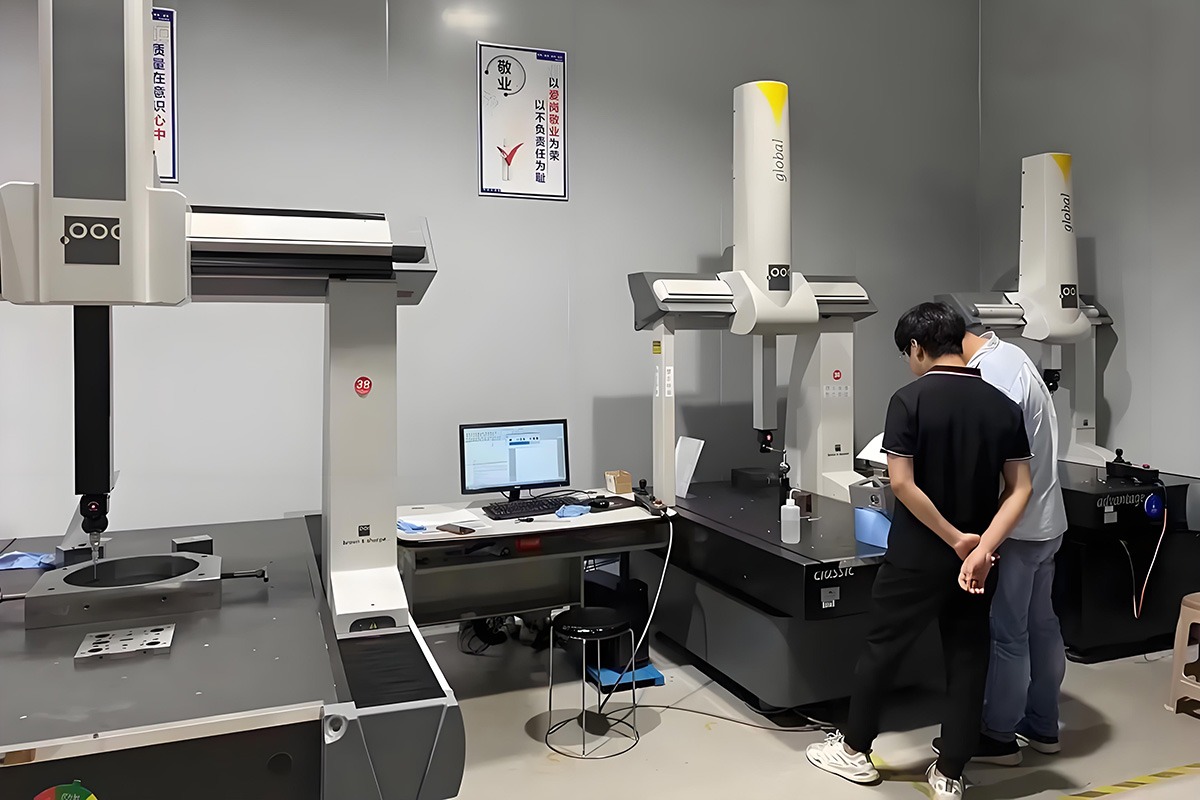

Inspection Workshop

Heating Treatment

Warehouse

Why Global Customers Choose JC Casting As Their Developing Partner.

One-Stop Manufacturing Solution

Casting → CNC Machining → Heat Treatment → Surface Finishing

Strong Custom Capability

95% orders are drawing-based OEM custom parts

More Material Expertise

Extensive experience Stainless Steel/Bronze/Aluminum/Titanium

Fast & Professional Communication

12h response · Engineers directly involved in RFQ

Stable Quality System

ISO 9001 / Process inspection / Dimensional control

How Can We Control the Quality?

From purchasing, design, production, inspection, each department has its own role. Each group has its own strict workflow and duties.

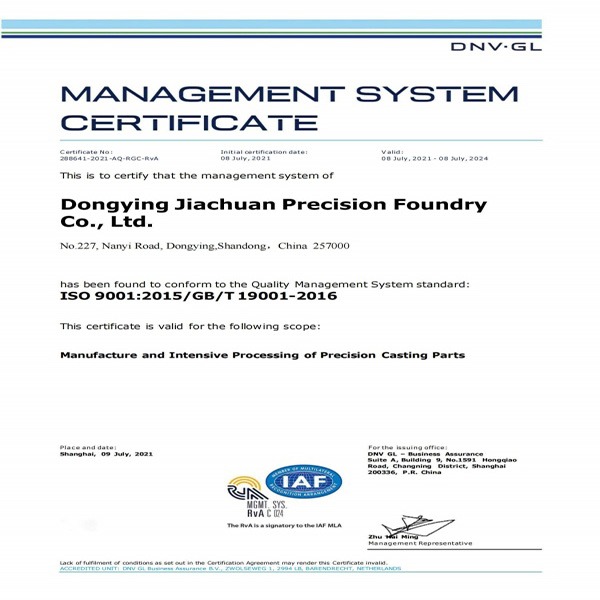

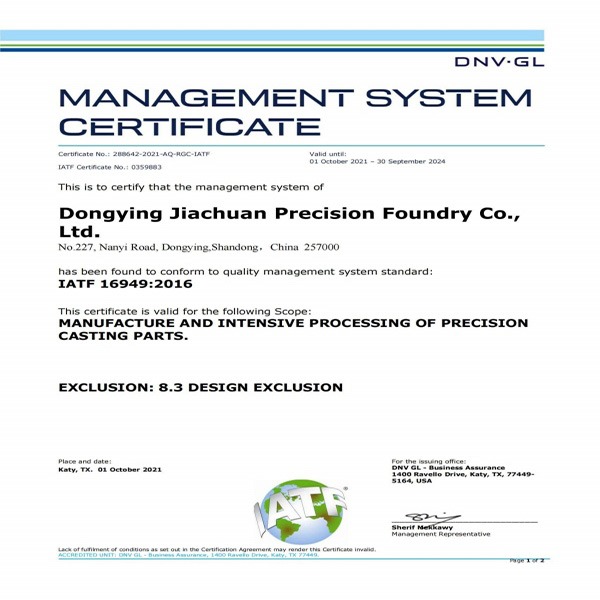

We have passed ISO 9001,IATF16949,CE quality system. All products are manufactured to the highest standards

Starting with the raw materials, our procedures are strictly documented and monitored. This process is carried out at every stage of production: molds, waxing, material analysis, blanks, machining.

In addition to basic visual inspection and caliper testing, we also offer coordinate measuring machines (CMM), salt spray testing, strength and yield testing!

If you are looking for professional guidance or customized casting solutions,Please contact our technical team to discuss casting technologies in more depth.

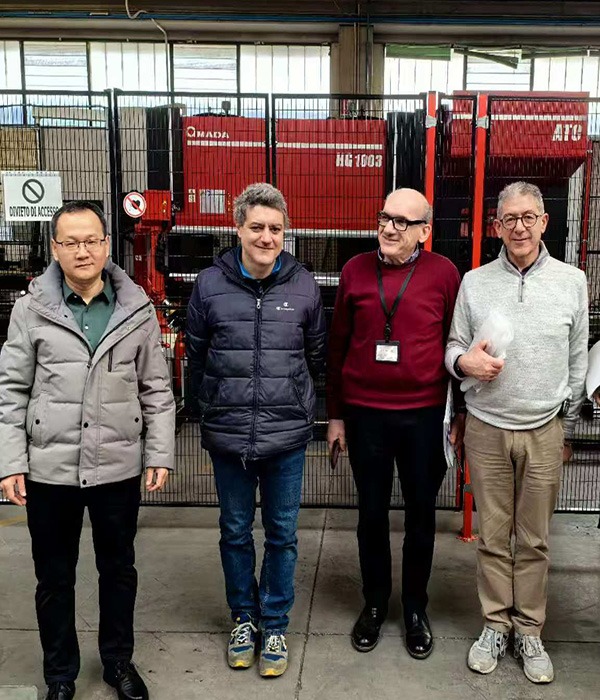

Our Clients

Trusted by global customers for precision casting solutions. Quality, reliability, and engineering support that turn complex designs into dependable cast parts. If you are looking for a foundry you can rely on, let’s discuss your project.

Common Questions

FAQ

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

If You Are Looking for a Reliable Precision Casting Supplier?

Now just tell us what you need. The Exclusive Plan will be delivered immediately.

No matter from Mold, Product Design, Technology Choosing, Cost Control, we have rich experience and professional engineer!

Email: info@jccasting.com

24 Hours WhatsApp: +86 181 054 67890