Large Impeller

The large impeller is a power machinery with continuous rotating blades as the main body, enabling the mutual conversion of energy between fluid working medium and shaft power.

JC Casting is a large impeller manufacturer. The main raw materials can be carbon steel, stainless steel, brass or titanium alloy.

We manufacture large impellers by using investment casting technology, sand casting or lost foam casting.

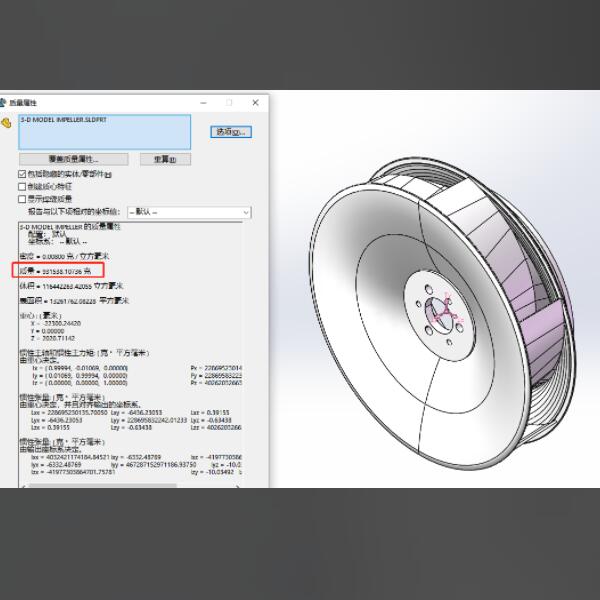

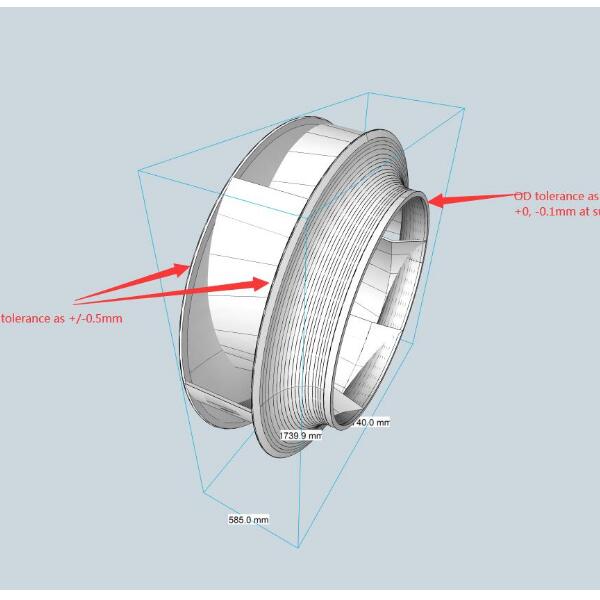

Until now, the biggest size we manufactured is 2m diameters. Then machining it by CNC, balancing it to achieve a finished product.

If you need a big impeller, you can send us the RFQ with details. Such as the material types, dimensions, tolerance. We can reply to you soon!

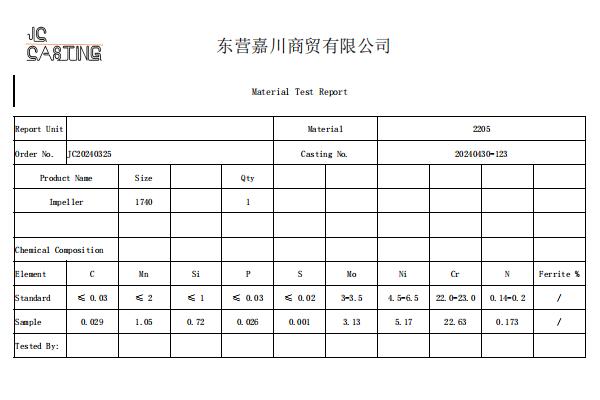

Below we, as a large impeller manufacturer, will show you how to manufacture a large impeller. —–The photo is 2205 stainless steel impeller.

Stainless Steel Large Impeller Manufacturing Processing

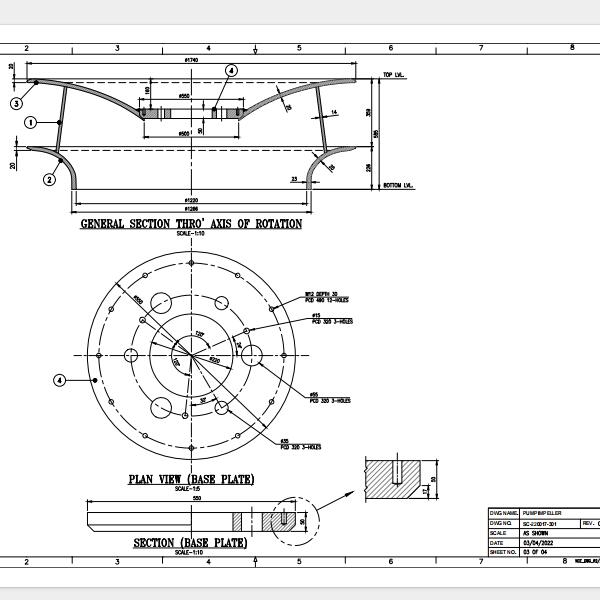

1-Drawing Analysis

After receiving the customer’s drawing, our technicians will make an analysis in the first time. Mainly from the following items:

Product dimensions, maximum diameter, minimum size, wall thickness, casting angle.

Material requirement, is it special? The material of this large impeller is 2205 duplex stainless steel. Because of the large size, high strength is required. The impeller is used on a ship for the customer’s application. It needs strong corrosion resistance. 2205 has these characteristics and is the optimal choice.

Then confirm what casting process is the most cost effective? Then they will meet with our production staff to discuss.

How long is the entire production cycle? What problems occur during production? Which process is critical? Then develop a detailed production process and distribute it to each production department.

Also we account for the final cost. Then we quoted the best price to our client. After getting our customer’s approval, our cooperation is concluded. Next we started the production.

2—Tooling

The first step in producing a casting is always to produce a mold.

According to the size of the product, the number of orders we decide the material of the mold.

Above large impeller mold is made of wooden mold.

If the order quantity is very high and repeated orders will follow. We then choose a mold with a strong and durable vitality. For example, a steel mold. Although the cost of such a mold is more expensive, the cost of the mold will be gradually offset in the later production process as the number of products increases.

If the order quantity is small, then we can choose a cheaper cost mold. For example, wooden molds. This will greatly reduce the cost of the customer.

3—Casting/Pouring

After the mold was produced, the next step is to cast it.

It is generally difficult to pour for such large impellers. For example, the location of the intersections. The speed at which the metal liquid is poured. Like this kind of large casting, the frequent problems are running and porosity, rising shell and other problems. This casting process is a great test of the factory’s production process and capacity.

4–Cutting

Once the blank has cooled down it can be simply cut. In this way the blank is produced.

5–Blank Casting Inspection

After finishing the blank casting, the quality has to be inspected. Nowadays, the main inspection methods are Dye penetrant inspection and X-ray testing.

The following pictures are the tests we did by Dye penetrant inspection. We can see that the rough casting is very successful.

6—Machining

If the blank inspection is completed without problems, we can proceed to machining.

The machining of large parts requires large machines. With a diameter of up to 1.5 meters, it is very easy to machine large impellers.

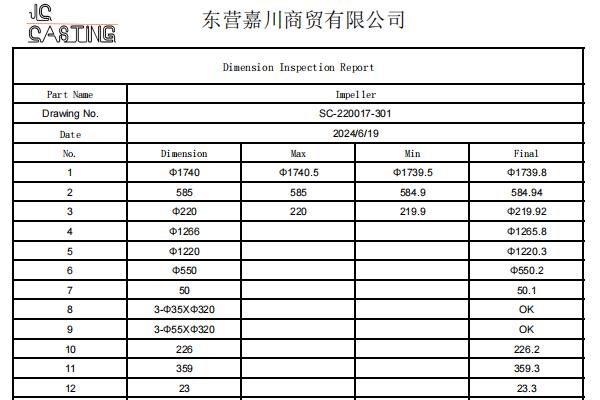

7—Inspection

After machining, we have to check the dimensions. Do the tolerances meet the customer’s requirements?

After the dimensional inspection is completed and there are no problems, we can proceed to the important step: dynamic balancing inspection.

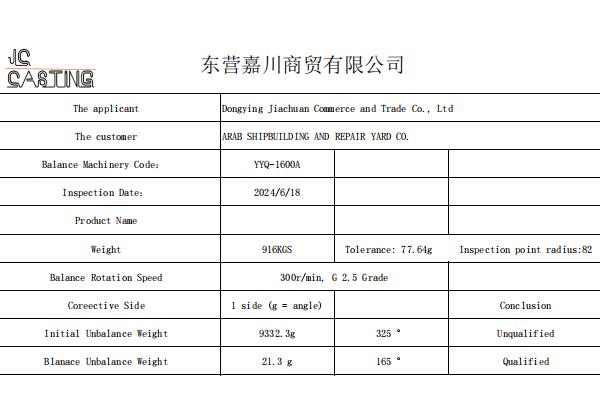

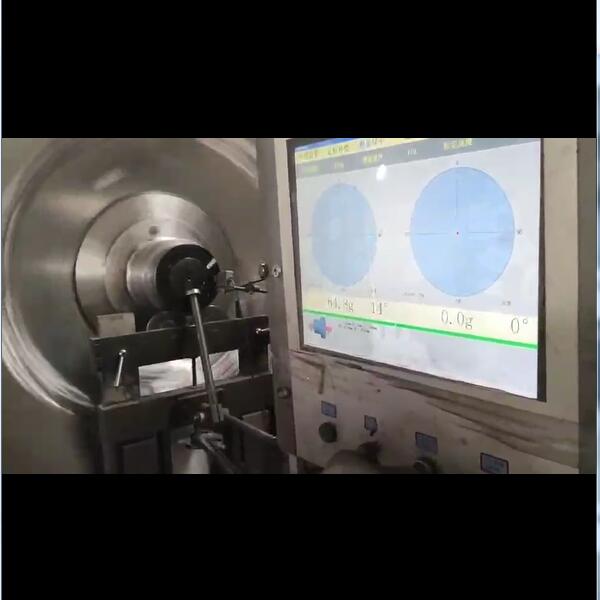

8—Blancing

According to the results of the dynamic balancing test, we can use the debugging block to adjust the dynamic balancing performance of the product. The final dynamic balancing effect is achieved.

Above is our process of producing stainless steel large impeller .

In addition to ss2205 material, 17-4, 304, 316 are also the materials we use.

In addition to stainless steel, carbon steel, copper, aluminum, titanium alloy is also our casting impeller material. If you have any products about impeller, such as double suction pump impeller, fan impeller, turbine impeller, etc., you can send email to us directly.