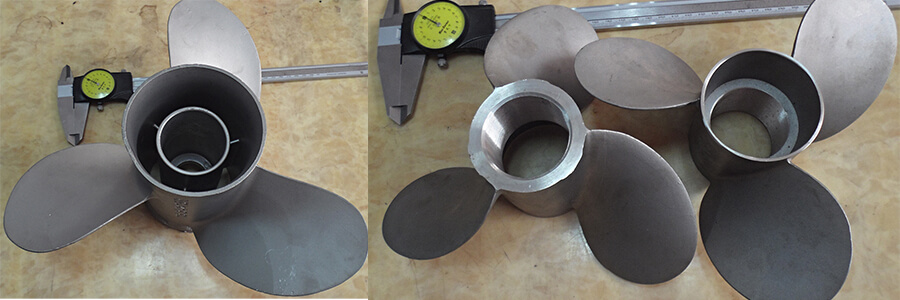

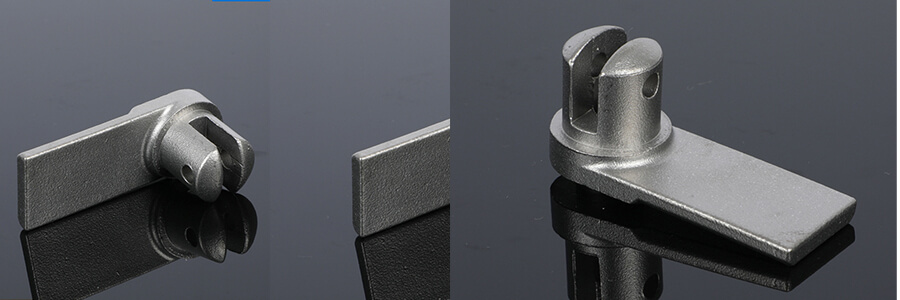

Duplex Stainless Steel (Duplex Stainless Steel) has superior corrosion resistance and high strength. It is widely used in chemical, petroleum, and marine engineering fields. SS2205 and SS2507 are the two most common types of duplex stainless steel. JC Casting is an SS2205 and SS2507 Casting manufacturer.

This article compares the differences between these two materials. From the chemical composition, mechanical properties, corrosion resistance and application scenarios.

Compositional differences

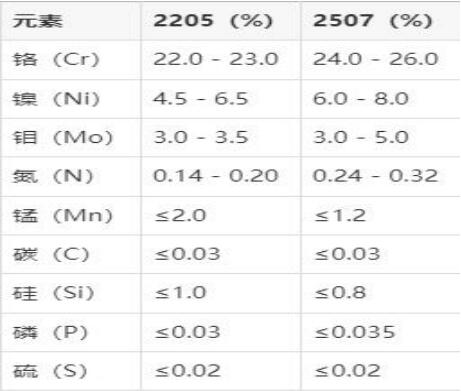

Comparison of chemical composition

The main alloying elements of 2205 and 2507 are chromium (Cr), nickel (Ni), molybdenum (Mo) and nitrogen (N). These elements determine the difference in their properties. The following table lists their typical chemical compositions:

The primary composition of 2205 duplex stainless steel includes 22% chromium, 5% nickel, 3% molybdenum, and a small amount of nitrogen (at about 0.18%). This combination gives it excellent corrosion resistance. Especially in chloride environments.

The 2507 duplex stainless steel contains 25% chromium, 7% nickel, 4% molybdenum and a small amount of copper (about 0.5%). Its composition is more complex.

In the table, SS2507 has a higher content of chromium, nickel and molybdenum than SS2205. This gives SS2507 superior corrosion resistance and higher strength.

Performance Comparison

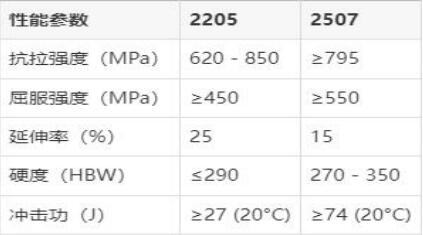

Mechanical Properties Comparison

On the mechanical properties, both 2205 and 2507 have high strength and toughness. They are suitable for applications subject to high pressure and high strength requirements. The following are typical mechanical property parameters for both:

2205 duplex steel has a tensile strength of approximately 620 MPa, a yield strength of approximately 450 MPa, and an elongation of approximately 25%.

The tensile strength of 2507 duplex steel is about 800 MPa, the yield strength is about 550 MPa, and the elongation is about 15%.

The tensile and yield strengths of 2507 are significantly higher than 2205, and it is also harder.

However, the elongation is slightly lower than 2205. This means that 2507 is better suited for applications in extreme environments. This means that 2507 is better suited for applications in extreme environments. But 2205 has better plasticity for moderate strength requirements.

Corrosion resistance

Duplex stainless steel due to its combination of austenitic and ferrite organization structure. It has good corrosion resistance. SS2205 and SS2507 both excel in a variety of corrosive environments. Especially in chloride-containing environments.

The following is a comparison of the corrosion resistance of the two in common corrosive media:

| Corrosion type | SS2205 | SS2507 |

| Potentiometric pitting (mV) | 700-1000 | >1050 |

| Critical pitting cracking(°C) | 35-45 | 45-60 |

| Stress corrosion cracking | Good | Best |

| Corrosion resistance in seawater environment | Better | Best |

2507 performs better than 2205 in terms of pitting potential and critical pitting temperature, especially in seawater environments. The corrosion resistance in chloride-containing media is even more outstanding. Its chloride stress corrosion resistance is about twice that of 2205 duplex steel. It is an ideal material for marine engineering and other highly corrosive environments.

Comparison of application scenarios

Due to the different performance of 2205 and 2507, they differ in practical applications.

2205: Commonly used in piping systems, heat exchangers, chemical storage tanks, etc. in the oil and gas industry. Due to its good corrosion resistance and high strength, and at the same time has a certain economy. It is a widely used type of duplex stainless steel.

2507: Due to its extremely high strength and excellent corrosion resistance. Suitable for more demanding environments. Such as marine engineering, seawater desalination equipment, chemical carriers, nuclear industry. Its higher alloy content makes it more costly. But it shows unrivaled advantages in critical applications.

Price and market availability

Due to the more complex composition and superior properties of SS2507. The price is usually higher. The actual price is also affected by market supply and demand, production costs, regional differences and other factors.

The corrosion resistance of duplex steels is also important. 2507 has a high chromium and molybdenum content. This makes it more resistant to pitting corrosion. It is particularly suitable for seawater environments. When choosing, it must also consider the actual use of the environment.

Conclusion

2205 and 2507 are representative materials of duplex stainless steel. Both have high strength and excellent corrosion resistance.

2205 is suitable for general industrial applications. Balanced performance and cost.

2507 with its higher strength and better corrosion resistance. Suitable for more demanding environments.

The comparison shows that while 2507 has superior performance, it is more costly. It is suitable for use in very demanding environments. While 2205 is due to its economy and good performance. It is commonly used in a wider range of industrial applications.

If you have any SS2205 or SS2507 casting inquiries, contact us freely! Info@jccasting.com