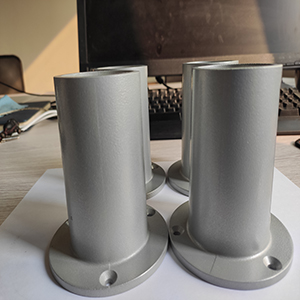

A356 Aluminum Casting

A356 is a kind of aluminum alloy with good casting performance, high strength and excellent surface quality.A356 aluminum castings are commonly used in automotive parts, mechanical equipment and aerospace, etc.A356 aluminum castings have good corrosion resistance, compressive strength and fatigue strength. It also has excellent processing performance. The microstructure can be controlled and adjusted through the machining process.

JC Casting is an Aluminum Casting Foundry which is specializing in pouring castings of different aluminum alloy. Especially A356.

JC Casting is an Aluminum Casting Foundry which is specializing in pouring castings of different aluminum alloy . Especially A356.

If you have inquiry about the A356 casting or other grade aluminum casting, you can email us now: info@jccasting.com

A356 Aluminum Casting Alloy Chemical Composition

ASTM A356 aluminum alloy is the common aluminum casting material. The A in front of an alloy designation means a higher purity version of the chemical composition. The differences are in the impurity levels allowed for Fe, Cu, Mn, Cr, Zn, and Ti and are as follows (all maximums):

A356(AlSi7Mg0.3) Aluminium Alloy is very common in Sand Casting Foundry and permanent mold aluminum castings Foundry, Die Casting Factory. There are 3 Grades: A356.0; A356.1; A356.2. Below are the Chemical Properties.

| Geade | Si | Mg | Fe | Cu | Zn | Mn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| A356.0 | 6.5-7.5 | 0.25-0.45 | 0.2 | 0.2 | 0.1 | 0.1 | 0.2 | Rest |

| A356.1 | 6.5-7.5 | 0.3-0.45 | 0.15 | 0.2 | 0.1 | 0.1 | 0.2 | Rest |

| A356.2 | 6.5-7.5 | 0.3-0.45 | 0.12 | 0.1 | 0.05 | 0.05 | 0.2 | Rest |

3 Top Casting Methods for A356 Aluminum Alloy

Permanent Mold Casting

Permanent Mold Casting ,also known as gravity die), is the most favored casting method for A356 aluminum alloys in numerous industrial fields. It is suitable for manufacturing numerous parts weighing up to 10 kilograms. Although it has a relatively slow pouring speed, it effectively utilizes gravity and solidifies more quickly. The mold castings also display outstanding mechanical properties, leading to a smooth and automated surface finish.

Die Casting in A356 Aluminum

It is less costly as it doesn’t necessitate complex machinery to inject metal into the mold.

It minimizes the waste of time and resources since the molds can be reused.

It solidifies rapidly, creating high-quality casts that require less post-processing.

It can be carried out manually or automatically.

Investment Casting

This method is extremely useful for designing complex parts made of A356 cast aluminum.

It offers a wide range of sizes. Investment casting can manufacture parts weighing up to 1000 pounds.

It can create impossible configurations that cannot be achieved by machine tools.

Advantages of A356 Aluminum Casting

- Excellent corrosion resistance

- Good weldability characteristics

- Mechanical properties are excellent

Compared to cast stainless steel alloys, the A356 aluminum alloy is extremely corrosion resistant but lightweight. Its strength characteristics are improved by heat treatment. They are used in the heat-treated condition of T5 and T6 hardness properties. Our A356 alloy casting weights between 0.2kg to 20kgs. Small to large volumes are acceptable.

A356 Aluminum Casting Heat Treatment Proces

There are two heat treatments for A356 alloy:T5 and T6.

T5 heat treatment is the simpler option for our castings where the aluminum extruded is allowed to naturally cool.

T6 heat treatment of A356 aluminum castings is more complex. It needs 2 steps. Firstly, the castings cool naturally. Then heated at a high temperature and instantaneously cooled in water. This method increased its hardness.

A356 Aluminum Casting Mechanical Properties

The composite composition of A356 makes it a strong, lightweight and corrosion resistant alloy. It is commonly used in structural and high-temperature applications. It is often a necessary material where weight reduction is required without sacrificing strength.

| Temper | Ultimate Tensile (ksi) | Yield Strength (ksi) | Brinell Hardness (500 Kg) | Shearing Strength (ksi) |

|---|---|---|---|---|

| T6 | 33 | 24 | 70 | 26 |

Applications of A356 Aluminum Casting with T6 Heat Treatment

A356 Alloy casting part is commonly used to make many parts.

- Pump component

- Flywheel castings

- Automotive transmission cases, oil pans, pump bodies, housings

- High strength air-frame and space frame structural parts

- High strength machine parts, truck chassis parts

- High-velocity blowers and impellers

- frames and bases.

It can be the aluminum alloy 6061 substitute.

A356 Aluminum Casting Secondary Operations

1-Post Machining.

Sometimes precise tolerance or smoother surface,post-machining is required to meet the specification. High precision CNC machining, milling, drilling, tapping.

2-Surface Finishing

Surface finishing ways like Painting, sanding, shot blasting, powder coating, chrome plating are available