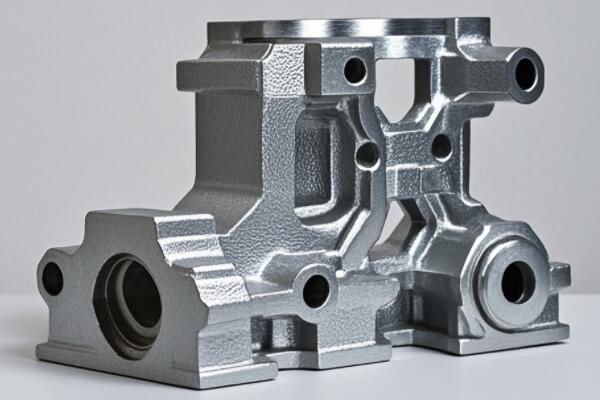

Alloy Steel Casting

JC Casting is an Alloy Steel Casting manufacturer and exporter. We can cast different alloy steel casting grades for different applications.

Alloy steel refers to the steel made by adding one or several alloying elements to carbon steel. The total weight of alloy steel elements can be 1.0% to 50%. It can improve the mechanical properties of steel.

There are two main categories of alloy steel: low alloy steel and high alloy steel. Mostly, the investment alloy steel casting is low alloy steel.

What is Alloy Steel Casting

Alloy steel casting is a steel casting process. It is a casting manufacturing method or process to pour the molten alloy steel into the shell to get a product with specific shapes and requirements.

Advantages of Alloy Steel Casting

- Excellent mechanical properties: high hardness and wear resistance

- Design flexibility, metallurgical versatility, and large weight and size range

- Good weldability and workability.

- Outstanding corrosion resistance, thermal and electrical conductivity

- Fully recyclable.

Alloy Steel Grades for Casting

Strictly speaking, every type of steel can be regarded as an alloy. However, not all steels are “alloy steels”. The simplest form of steel is an alloy composed of iron (Fe) and carbon (C). With carbon content ranging from approximately 0.1% to 1%, depending on the specific type of steel. But, the term “alloy steel” specifically efers to steels with other alloying elements added deliberately in addition to the carbon.

Manganese (the most common one), nickel, chromium, molybdenum, vanadium, silicon, and boron are the common alloying elements.

Aluminum, cobalt, copper, cerium, niobium, titanium, tungsten, tin, zinc, lead, and zirconium are included in the category of less common alloying elements.

Below are the common Alloy Steel Grades

Alloy Steel Casting manufacturer and exporter

We have advanced mechanical equipment and a professional technical team. No matter very small tolerances, the complex shape of the casting, or the surface details, we are confident to help you deal with these problems.

Besides the Basic Alloy Steel Castings Product, we can supply

- chrome alloy castings,

- copper-nickel alloy casting,

- copper-zinc alloy castings,

- gold alloy castings,

- nickel alloy castings,

- high alloy castings,

- titanium castings

- high nickel alloy castings.

Alloy Steel Investment Casting Capabilities

- Mold design,

- Prototype development

- Casting Production,

- High-precision machining

- Surface Finishing: Polished galvanized, nickel-plated, electroplated, chrome-plated,Anodizing, phosphating, acid treatment, polishing, Surface grinding, sandblasting, powder coating

- Machining: Broaching, milling, drilling, tappingHeat treatment

- Value-added one-stop solutions

- Qualification and testing