Both SS2205 and SS2207 belong to duplex stainless steel. They combine many of the good properties of ferritic and austenitic steels. But, there are significant differences between them in many aspects. JC Casting is a S2205 casting and SS2207 casting manufacturer. Here, we would like to introduce the difference between them.

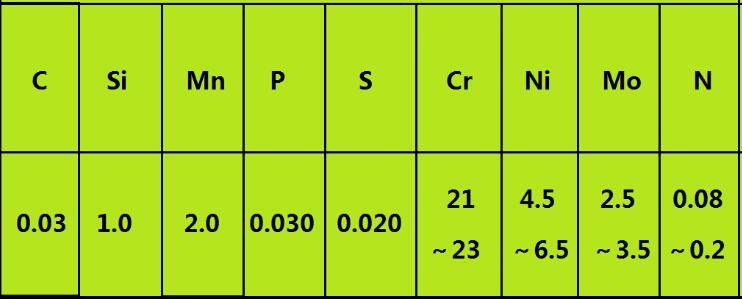

Chemical composition

2205 duplex stainless steel is composed of 21% chromium, 2.5% molybdenum,4.5% nickel-nitrogen alloy.

2207 Duplex Stainless Steel: Has a high chromium and molybdenum content with excellent corrosion resistance.

Its chemical composition usually consists of iron, chromium (precisely controlled within a specific range to ensure good corrosion resistance).

Nickel (added in moderate amounts. Optimizes the toughness and ductility of the material). Molybdenum (significantly enhance the ability to resist pitting and crevice corrosion) and other elements.

Mechanical properties

SS2205:

- High strength and good impact toughness.

- Good overall and local resistance to stress.

- Corrosion ability.

- But, due to its high strength, bending and molding may be relatively difficult.

SS2207:

- its strength and hardness is usually higher than 2205.

- Able to withstand greater loads. This gives 2207 an advantage in applications requiring high strength and corrosion resistance.

- Also, 2207 has a lower coefficient of thermal expansion and higher thermal conductivity. In the environment of large temperature changes can maintain good stability.

Corrosion resistance

2205 duplex stainless steel: excellent performance in a variety of atmospheric environments. Including corrosion resistance in seawater.

However, it is not suitable for use at temperatures above 300C. Because it will precipitate brittle microscopic components. Also avoid temperatures below -50C. Because of its plasticity, brittleness will transform.

2207 Duplex Stainless Steel: Due to its higher molybdenum and nickel content, it is superior in resistance to pitting, crevice and uniform corrosion. Especially in environments containing chloride ions. 2207’s resistance to corrosion far exceeds that of ordinary stainless steel. At the same time, it also has good oxidation resistance. In the high temperature and oxidizing environment can maintain the stability of the surface.

Processing performance

2205 duplex stainless steel: it is relatively easier in processing and molding. Its degree of work hardening is low.

2207 duplex stainless steel: due to its high strength and hardness. Processing requires higher energy. More fine process control.

Applications

SS2205: widely used in chemical processing, transportation and storage industries.

SS2207: often used in the oil and gas industry for heat exchanger tubes, water treatment and water supply systems, fire-fighting systems, water spray systems.

In the field of petrochemical equipment, it can be used in desalination (desalination) equipment and a variety of mechanical and structural components that need high strength and high corrosion resistance.

Price

Price: Due to the more superior performance of 2207, its price is usually higher than 2205.

Cost-effective: Although the price of 2207 is higher. But its excellent performance in high-strength and highly corrosive environments makes its cost-effective is still very high. In contrast, 2205 offers good performance and cost-effectiveness in a wider range of application scenarios.