Integrated Metal Casting Foundry with CNC Machining Company

We focus on customized casting products based on design and idea. Then mass production at our factory!

Integrated Investment Casting Foundry and CNC Machining Company

JC Casting is your reliable one-stop metal casting and CNC machining supplier for custom manufacturing from prototyping to production. Prompt Communications,Superior quality with fast delivery!

About Us

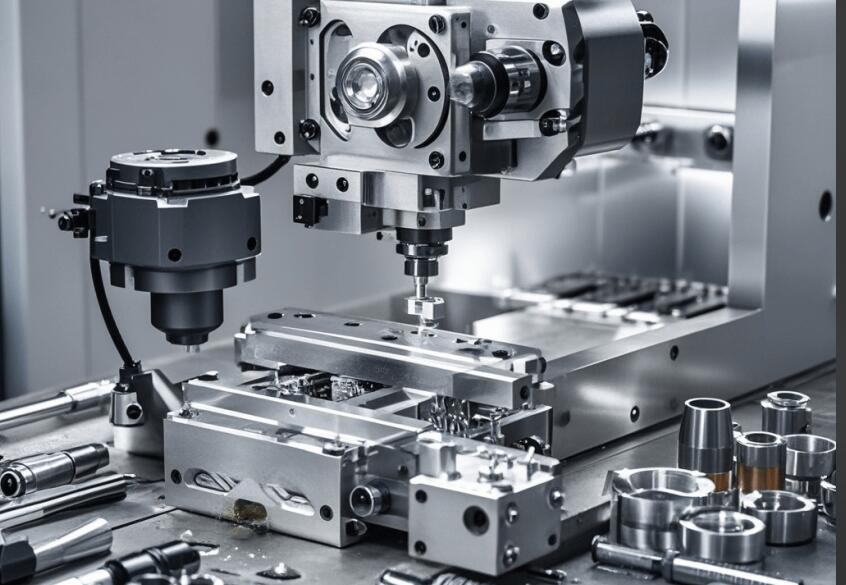

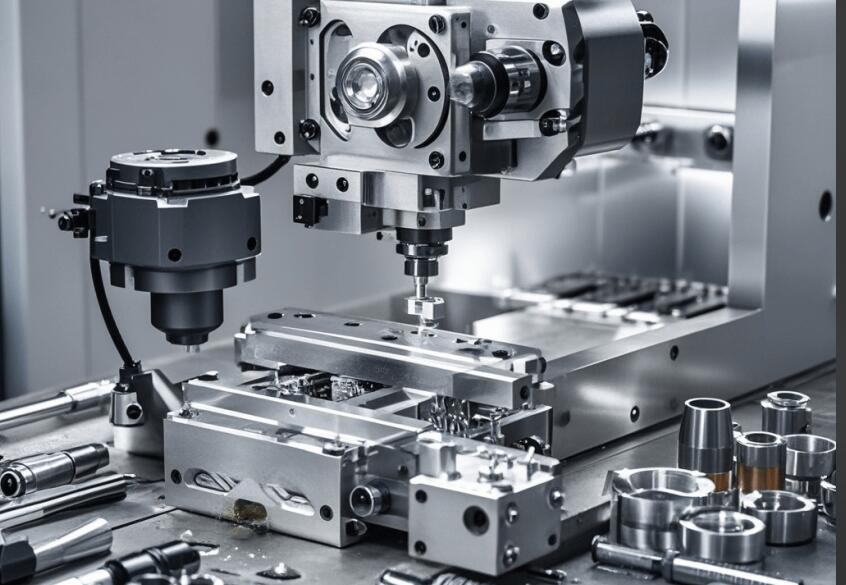

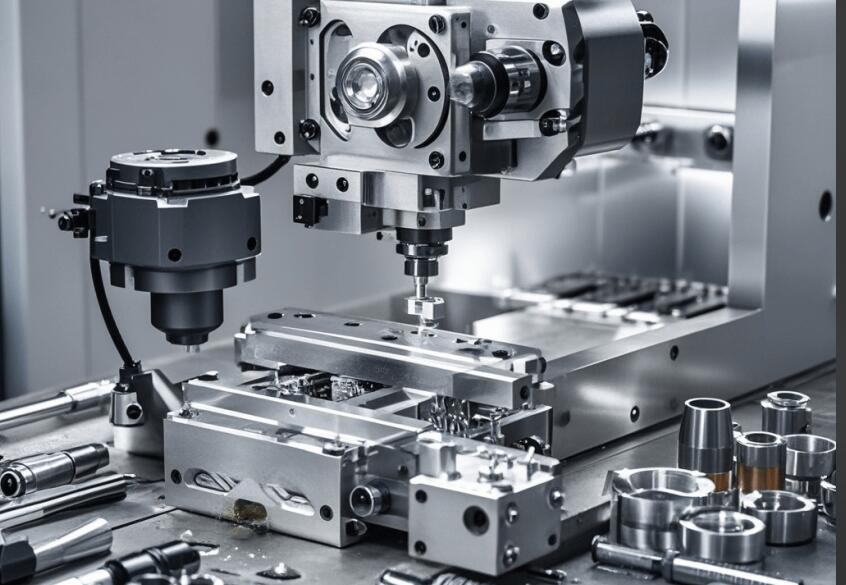

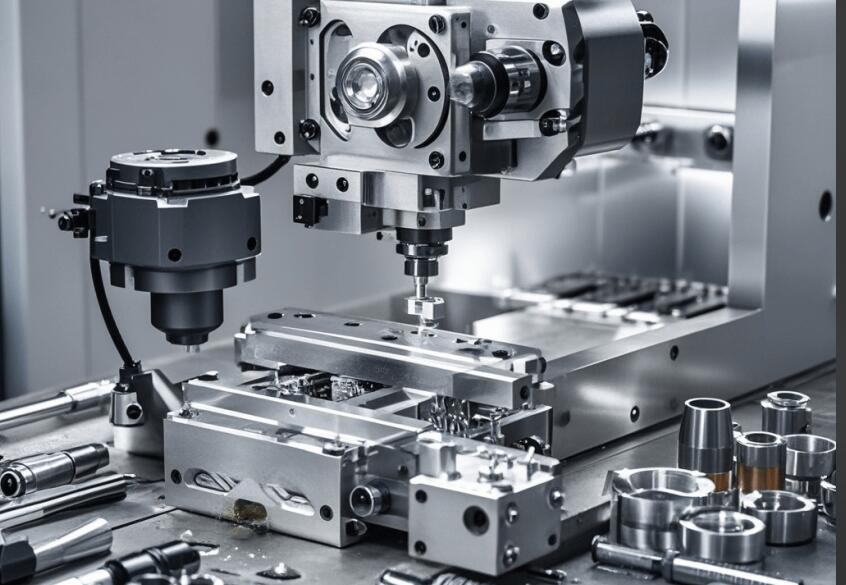

JC Casting Foundry is specializes in investment casting, die casting and CNC Machining processes. We can cast different shapes of parts to meet our client’s specific design and specifications.

Also,like CNC machining,surface finishing,many value-added services are available. If you are looking for a reliable casting partner in China, JC Casting Foundry is your best choice!

Our Manufacturing Services

We can provide 3 main manufacturing processes and CNC machining service. Accept multiple types and small orders.

Investment Casting

Investment casting is a precision manufacturing process in which a wax pattern is coated with a ceramic shell. The wax is melted out. Then molten metal is poured into the resulting cavity to create highly accurate metal parts.

Typical Metal Casting Products

Stainless Casting

Stainless steel is known for its excellent corrosion resistance. It is an ideal material for casting components in industries. Such as food machine, marine, and chemical industry. JC casting use the latest precision casting techniques to make high-accuracy stainless steel casting parts. Usually requiring little to no additional machining. Common stainless steel grades we used : 304(L), 316(L), 17-4 PH, and 2205 duplex.

Carbon Steel Casting

Carbon steel casting is highly valued for its good strength, ductility, and cost – effectiveness. It is used in various industries, such as construction, automotive, and heavy machinery. JC Casting manufactures high – quality carbon steel casting parts with precise dimensions, excellent surface finishes, and good mechanical properties, reducing the need for post – casting machining. Common carbon steel grades we use include: Q235 (equivalent to ASTM A36), Q345, ASTM A335, DIN C35 (1.0501), and C45 (1.0503).

Alloy Steel Casting

Alloy steel casting has features of outstanding strength, durability, and versatility. It contains specific alloying elements. Widely used in high-stress applications: aerospace, automotive, and heavy machinery industries. JC Casting can meet strict performance standards, delivering reliable solutions for demanding projects. Popular grades: 20CrMo, 4140 and 4340.

Aluminum Casting

Aluminum casting is good at light weight, excellent corrosion resistance, and high thermal conductivity. It is widely used in aerospace, automotive, and electronics. JC Casting produce top-quality aluminum casting parts by die casting, sand casting process.These parts are accurate in dimensions, surface finishes, and outstanding mechanical properties. Common aluminum grades:A356, A380, and 6061 or special Al-Mg Alloy Casting.

Bronze Casting

Bronze casting is a long history high – quality product. Bronze is an alloy mainly composed of copper and tin, sometimes with other elements. We can produce bronze casting parts by sand casting and investment casting process. Common bronze grades we use: C90300 (SAE 64), C93200 (SAE 660), and C95400.

Brass Casting

Brass casting stands as a well-established manufacturing method. It is renowned for its outstanding ductility, corrosion-resistant properties, and shining surface.Brass casting parts are used in various industries like plumbing, hardware, and decorative arts. JC Casting produces premium-quality brass casting products. Our brass castings distinguish themselves with accurate dimensions, smooth surface finish,good mechanical strength. The popular brass grades: C26000, C36000, and C46400.

Ti Alloy Casting

Ti Alloy casting parts are highly valued products. It is widely recognized for its exceptional strength-to-weight ratio, high-temperature resistance, superior corrosion resistance. Ti Alloy casting parts are widely used in aerospace, automotive and marine engineering. We use the Vacuum precision casting process and cnc machining. The popular Ti Alloy grades are Ti-6Al-4V, Ti-5Al-2.5Sn, and Ti-6Al-2Sn-4Zr-2Mo.

Iron Casting

Iron casting is a long-standing and reliable manufacturing process. Iron is featured for its excellent strength, durability,low material cost. It is an ideal material in industries such as construction, machinery manufacturing, and automotive. At JC Casting Foundry,we have sand casting and lost foam casting techniques to produce cast iron casting parts. We commonly use gray iron (ASTM A48),ductile iron (ASTM A536).

Application Industries

We Can Help You

What Service Are You Looking For?

Factory Construction

Factory Construction Products Design

Products Design Casting

Casting

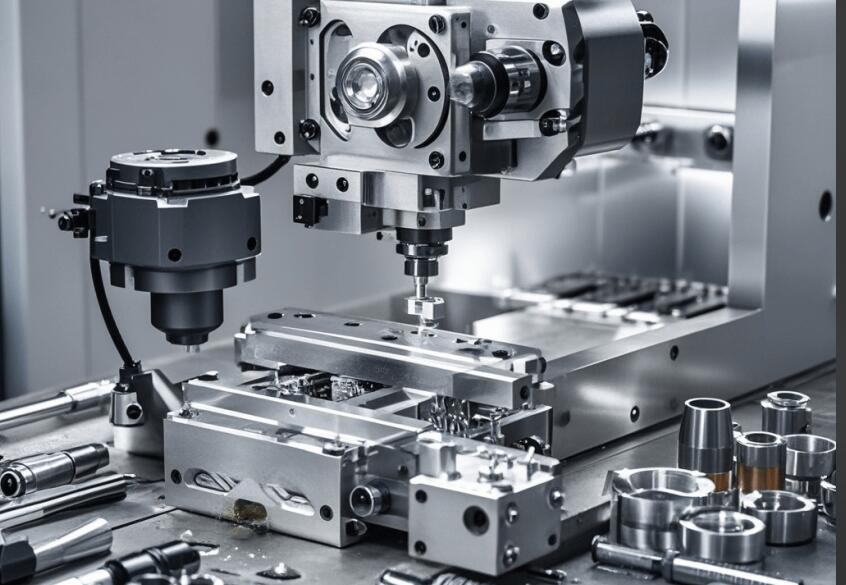

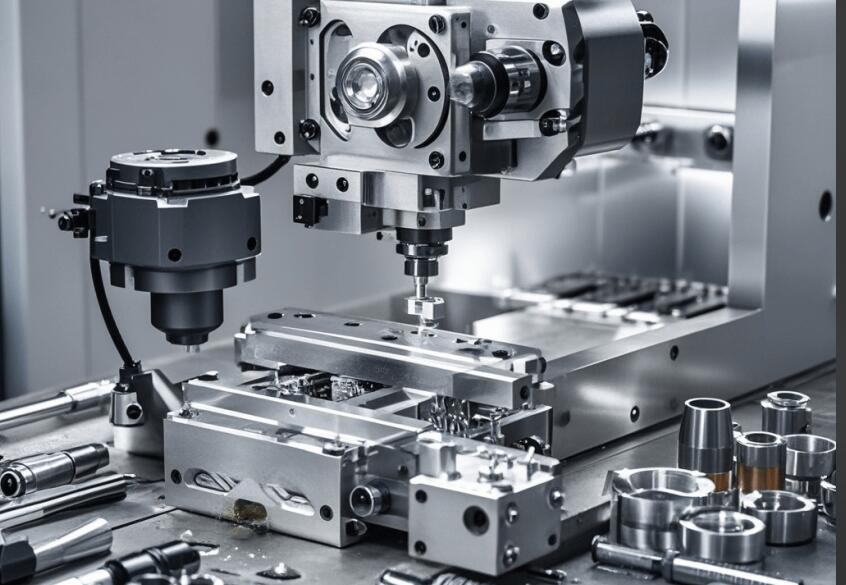

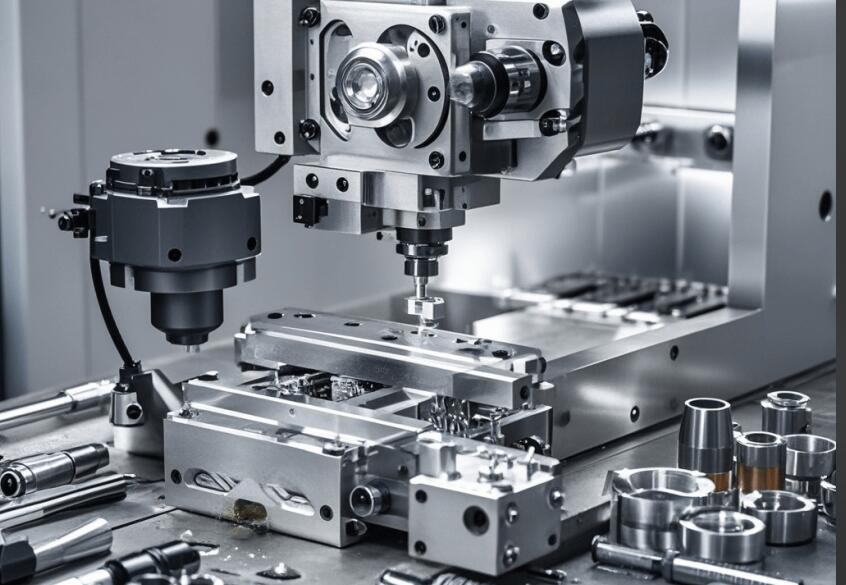

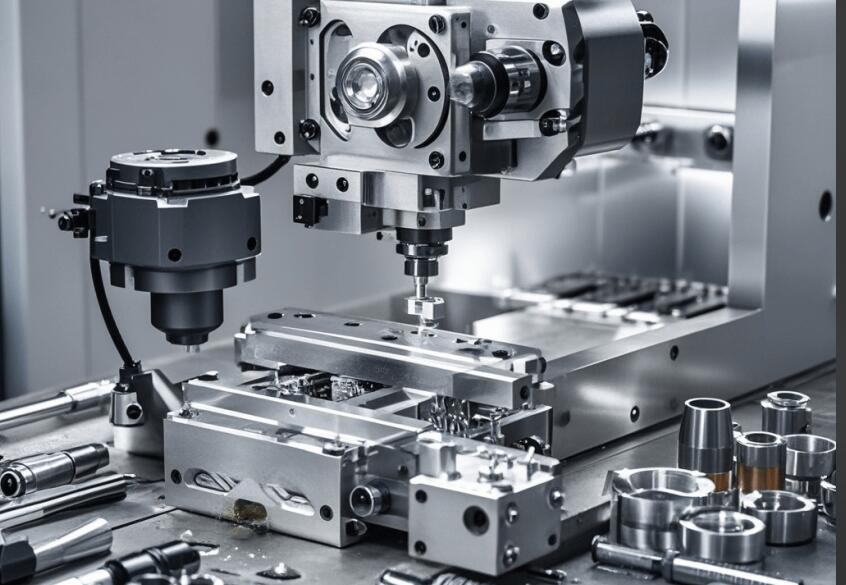

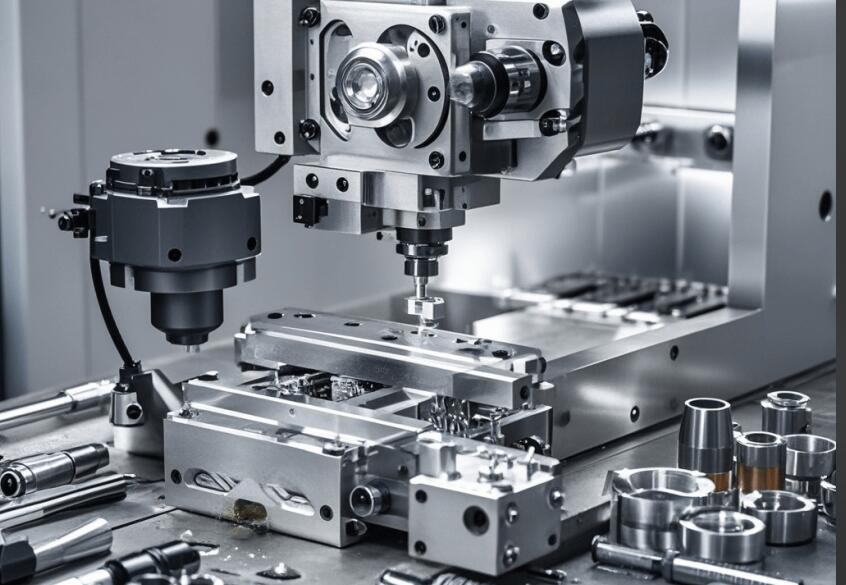

CNC Machining

CNC Machining Inspection

Inspection Assembling

Assembling

Besides casting manufacturing, other value-added services can be provided. Such as Polishing, Heating treatment,3D Printing (Wax or metal), PVD Coating, Electroplating and so on.

4 Main Casting Processes

As per the product’s material, requirement, quantity, we choose different manufacturing processes to achieve fast, economical and qualified results.

Silica sol Lost Wax Investment Casting

Suitable for products with high dimensional accuracy and surface quality requirements and complex shapes

Sand Casting

Suitable for big volume and heavy height casting parts with low dimension and finished surface requirement.

Water Glass Lost Wax Investment Casting

Suitable for products with less complex shapes and less demanding surface quality requirements. The cost advantage is much greater than the silica sol casting process

Die Casting

Suitable for high dimensional accuracy, high surface finish, high strength hardness, complex structure, especially batch products